MICRO-PERFORATED COOKING SURFACE

The special micro-perforated construction of the surface of the cooking plate, which allows pizzas to expel cooking moisture and deposit excess flour, and the high density plate construction material for better accumulation of heat ensuring better, cleaner and more fragrant cooking.

The oven pizza cooking plate construction material has a specific weight of 2800-3200 Kg/m³, compared to classic refractory material at 1800-2200 Kg/m³. This ensures better accumulation of heat and an enhanced thermal flywheel effect. The type of inert refractory material used for the cooking surface in our pizza ovens is about 6 times more resistant to abrasion than porphyry – thereby ensuring vastly superior resistance to rubbing with the pizza shovel compared to standard refractory materials.

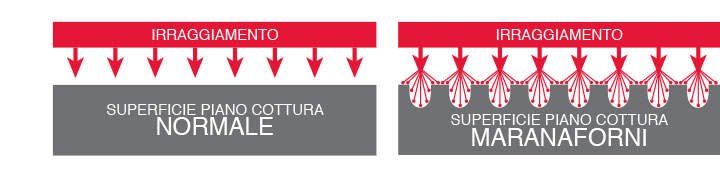

The refractory plate in a wood-fired oven is heated by radiation – i.e. the transfer of heat from a hot body to a cooler body without contact. For example, our bodies warm up when passing from shadow to sunlight or, in an oven, a pizza cooked by flame irradiation. The surface of the plate is designed to maximise flame radiation. Our micro-perforated plate exposes to flame irradiation a surface 50% larger than for a conventional plate, thereby achieving better and faster accumulation of heat in the pizza oven (see drawing).